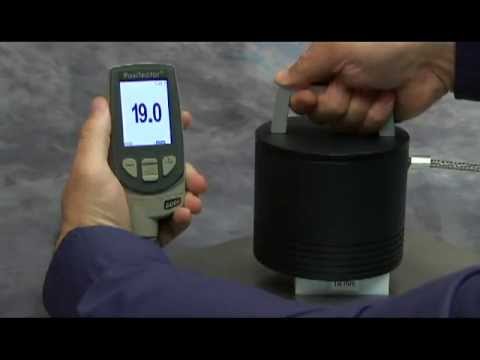

PosiTector® 6000 Series

Durable

- NEW Weatherproof, dustproof, and water-resistant—IP65-rated enclosure

- NEW Ergonomic design with durable rubberized grip

- Wear-resistant probe tip

- Shock-absorbing, protective rubber holster for added impact resistance

- Two-year warranty on gauge body AND probe

Versatile

- PosiTector body accepts all PosiTector 6000, 200, DPM, IRT, RTR, SPG, SST, SHD, BHI, and UTG probes easily converting from a coating thickness gauge to a dew point meter, surface profile gauge, soluble salt tester, ultrasonic wall thickness gauge, or hardness tester

- Multiple Calibration adjustment options including 1 point, 2 point, and ISO 19840 correction factors

- Selectable display languages

- NEW Auto rotating display with Flip Lock

- Extended cables available (up to 75 m/250 ft) for underwater or remote measuring

- Mils/Microns/mm switchable

Standard Models

- NEW Storage of 1,000 readings per probe—stored readings can be viewed or downloaded

Advanced Models

- NEW Storage of 250,000 readings in up to 1,000 batches and sub-batches

- Live graphing of measurement data

- NEW Prompted Batch Mode—create pre-defined batches with on-screen text and image prompts for each reading

- 3 Scan Modes — increase measurement speed to 180+ readings per minute

- Normal – take continuous readings without lifting the probe

- Statistics – take continuous readings and record average, standard deviation, min/max thickness and number of readings while scanning

- Limited Count Average – take continuous readings up to a user-specified count. The gauge displays and records the average of the readings.

- NEW Touchscreen keyboard for quickly renaming batches, adding notes, and more

- Multiple stored calibration adjustments for measuring on a variety of substrate conditions

- NEW Calibration Adjustment Reporting feature documents calibration adjustments into PosiSoft software reports

- NEW SSPC-PA 2, ISO 19840, and IMO PSPC 90/10 modes help users comply with standards by prompting for min/max specifications, displaying the necessary readings, and automatically calculating statistics with a pass/fail result

- WiFi technology wirelessly synchronizes with PosiSoft.net and downloads software updates

- Bluetooth 4.0 Technology for data transfer to a mobile device running the PosiTector App or optional portable printer. BLE API available for integration into third-party software

- Integrate with third-party software, drones, ROVs, PLCs, and robotic devices using several industry-standard communication protocols